Specification

| Model |

Motor Power HP/KW |

Lubricating oil (L) |

Capacity M3/min |

Pressure MPA |

Noise db (A) |

Dimension mm |

Weight kg |

| kp55kw-0.8-1.6mpa | 55KW/75HP | 54 | 13.4-12 | 0.8-1.6 | 60~70±2 | 2180*1430*1720 | 1580 |

![]()

The Other KAPA Air Compressors:

1) Screw Air Compressors ( Air delivery:0.8m³/min -72m³/min;Work pressure:8-13Bar;Power:7.5Kw-415kw)

2) Mining Air Compressors(Air delivery:1.8m³/min-13m³/min ;Work pressure:5-7Bar;Power 11Kw-108Kw)

3) Diesel Driven Portable Screw Air Compressors (Air delivery:6m³/min-1377m³ ,Work pressure:7-35Bar )

4) Motor Powered Portable Screw Air Compressors -(350CFM – 910CFM)

5) Explosion Proof Air Compressors - 30HP-120HP (22kw-90kw)

6) Diesel Driven Piston Small Air Compressors -15HP-25HP (11kw-18.5kw)

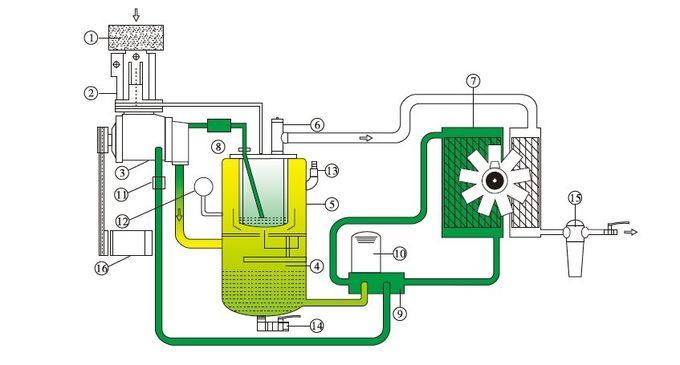

Working schematics

|

1. Air Filter |

9. Oil Temperature Control Valve |

| 2. Air-in Easing Value | 10. Oil Filter |

| 3. Air end | 11. One-way Shut-off Valve |

| 4. Oil Air Separator | 12. Pressure Gage |

| 5. Oil Air Separating Filter Core | 13. Safety Valve |

| 6. Minimum Pressure Valve | 14. Vent Valve |

| 7. Radiator with Aluminum Alloy Fans | 15. Compressed Air Dry Separator |

| 8. Return Check Valve | 16. Motor |

Advantages of Kapa brand

Innovate technology to protect the environment.

Kapa listens, understands and meets the needs of customers

Save the environment, ensure to provide better services and solutions, save costs for users, and seek the largest growth space. The main purpose is to protect and save energy, stimulate the growth of economic productivity, comply with market demand, save energy and reduce environmental pollution. With the mission of "innovation embodies value", Kapa Company will continue to promote technological innovation and progress, achieve win-win with global partners, suppliers and employees, create a new world of "energy saving, environmental protection, intelligence and service" in the aerodynamic field, and strive to be a world-class enterprise with world-class standards.

Advantages:

1. High quality control(CE,SGS,ISO14001/Energy saving certificate)

2. Fast Delivery( 25-30 days for large orders)

3. Good service for pre-sale,after-sale( strong technical support and professional after-sales team)

4. Small order acceptable( Ordering quantity according to your actual needs)

Why choose us

Longer service life of the master machine

The rotor uses asymmetrical line running at a low speed with the support of the ball bearings and roller bearings as a result. The damage and the cost are lowered and the service life is extended. Some force is counteracted by the axial force generated by the bevel gear. So the load on the bearings of the master machine is lowered.

Permanent alignment of the electromotor and the master machine

Different from the strap compressor, the SRC series compressor can integrate the electromotor with flange, shaft coupling box-gear box. and the master machine into one in such way the master machine and the electrometer are aligned forever in the transpiration. The SRC series compressors equipped with effective and fully sealed air-cooling electromotor.