22KW / 30HP Intelligent High Efficiency Industrial Air Compressor 1.8m³ / min

Application

traditional aerodynamics: pneumatic tools, rock drills, pneumatic picks, pneumatic wrenches, pneumatic sandblasting

instrument control and automation devices, such as tool replacement in machining center.

vehicle braking, doors and windows opening and closing

in the air-jet loom, compressed air is used to blow weft yarns instead of shuttles

food and pharmaceutical industries, using compressed air to stir slurry

Starting of Large Marine Diesel Engine

wind tunnel experiment, underground passage ventilation, metal smelting

oil well fracturing

high pressure air blasting coal mining

weapon system, missile launch, torpedo launch

submarine ups and downs, shipwreck salvage, submarine oil exploration, hovercraft

tire inflation

painting

Bottle blowing machine

air separation industry

industrial control power (driving cylinders, pneumatic components

producing high-pressure air for cooling and drying workpieces

Superior design with 42 types of technology patent, two stages compression, realize maximum energy saving and lowest noise level.

State-of-the-art screw element, original Germany DENAIR air end, advanced SAP profile design, superior Sweden SKF element bearings.

Adopts world-renowned components, such as Schneider electronics from France, Danfoss pressure sensor from Denmark, etc. contribute to guarantee the compressor longer

service life.

Stainless steel oil pipe and air pipe, high temperature resistant (400C=752F ) and low temperature resistant(-270C=518F ), high pressure resistant. Ultra-long life(80 years)

completely leak-free and maintenance-free.

Conform to CE,IS014001 and energy saving certification, etc.

Specification

|

Model |

kp22KW-1.6/YC |

| (M³/Min/Mpa) | 16bar |

| Power Kw/ HP | 22KW/30HP |

| Ambient Temperature ℃ | 2℃-45℃ |

| Cooling Mode | Air Cooled |

| Discharge Temp | ≤Ambient +15℃ |

| Noise Level Db(A) | 70±2 |

| Driven Mode | Direct Drive |

| Power (V/Ph/Hz) | 380V/3/50Hz |

| Starting Mode | VSD |

| Dimension (mm) | 1250*850*1140 |

| Net Weight (kg) | 365 |

| Out let Diameter (inch) | RP1 |

![]()

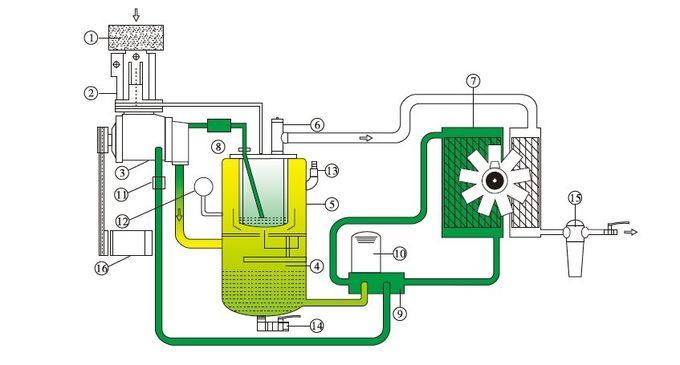

⊙ Schematics

| 1. Air Filter | 9. Oil Temperature Control Valve |

| 2. Air-in Easing Value | 10. Oil Filter |

| 3. Principal Screw Machine | 11. One-way Shut-off Valve |

| 4. Oil Air Separator | 12. Pressure Gage |

| 5. Oil Air Separating Filter Core | 13. Safety Valve |

| 6. Minimum Pressure Valve | 14. Vent Valve |

| 7. Radiator with Aluminum Alloy Fans | 15. Compressed Air Dry Separator |

| 8. Return Check Valve | 16. Motor |

why choose us

Longer service life of the master machine

The rotor uses asymmetrical line running at a low speed with the support of the ball bearings and roller bearings as a result. The damage and the cost are lowered and the service life is extended. Some force is counteracted by the axial force generated by the bevel gear. So the load on the bearings of the master machine is lowered.

Permanent alignment of the electromotor and the master machine

Different from the strap compressor, the SRC series compressor can integrate the electromotor with flange, shaft coupling box-gear box. and the master machine into one in such way the master machine and the electrometer are aligned forever in the transpiration. The SRC series compressors equipped with effective and fully sealed air-cooling electromotor.