18.5KW / 25HP 1.23m³ / min Intelligent High Efficiency Industrial Air Compressor 1950*910*1905

Description

Superior design with 42 types of technology patent, two stages compression, realize maximum energy saving and lowest noise level.

State-of-the-art screw element, original Germany DENAIR air end, advanced SAP profile design, superior Sweden SKF element bearings.

Adopts world-renowned components, such as Schneider electronics from France, Danfoss pressure sensor from Denmark, etc. contribute to guarantee the compressor longer

service life.

Stainless steel oil pipe and air pipe, high temperature resistant (400C=752F ) and low temperature resistant(-270C=518F ), high pressure resistant. Ultra-long life(80 years)

completely leak free and maintenance free.

Conform to CE,IS09001 and energy saving certification, etc.

Adpot high efficiency air end , low bearing noise, adopt oil fog shower cooling, holding body constant temperature movemet.

high efficiency, low noise motor, high protection grade, Wide range of applications

Long service life

large margin heat dissipation area design, heat dissipation effect is strong, avoid high temperature shutdown.

Design of intelligent heat dissipation fan, which can start and stop heat dissipation automatically according to temperature degree.

Using high efficiency oil and gas separator, the residual oil content is less than 3pDm, and the working temperature can reach 120.

Degrees Celsius. It has the advantages of low pressure drop and energy saving, long service life, low fuel consumption, reliable and stable performance.

The fixed particles of 25um can be filtered out by using high quality and high strength filter medium, and the working temperature can reach 120 degrees Celsius. It has long service life, corrosion resistance, reliable and stable performance.

Strong weather resistance, anti-aging, anti-ozone ultraviolet radiation

|

Model |

kp18.5KW-1.6/YC |

| (M³/Min/Mpa) | 1.23/1.6 |

| Power Kw/ HP | 18.5KW/25HP |

| Ambient Temperature ℃ | 2℃-45℃ |

| Cooling Mode | Air Cooled |

| Discharge Temp | ≤Ambient +15℃ |

| Noise Level Db(A) | 70±2 |

| Driven Mode | Direct Drive |

| Power (V/Ph/Hz) | 380V/3/50Hz |

| Starting Mode | VFS |

| Dimension (mm) | 1950*910*1905 |

| Net Weight (kg) | 620 |

| Out let Diameter (inch) | RP1 |

![]()

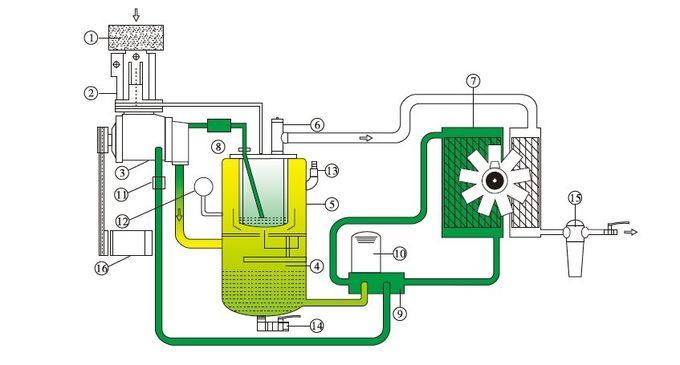

⊙ Schematics

| 1. Air Filter | 9. Oil Temperature Control Valve |

| 2. Air-in Easing Value | 10. Oil Filter |

| 3. Principal Screw Machine | 11. One-way Shut-off Valve |

| 4. Oil Air Separator | 12. Pressure Gage |

| 5. Oil Air Separating Filter Core | 13. Safety Valve |

| 6. Minimum Pressure Valve | 14. Vent Valve |

| 7. Radiator with Aluminum Alloy Fans | 15. Compressed Air Dry Separator |

| 8. Return Check Valve | 16. Motor |

why choose us

Longer service life of the master machine

The rotor uses asymmetrical line running at a low speed with the support of the ball bearings and roller bearings as a result. The damage and the cost are lowered and the service life is extended. Some force is counteracted by the axial force generated by the bevel gear. So the load on the bearings of the master machine is lowered.

Permanent alignment of the electromotor and the master machine

Different from the strap compressor, the SRC series compressor can integrate the electromotor with flange, shaft coupling box-gear box. and the master machine into one in such way the master machine and the electrometer are aligned forever in the transpiration. The SRC series compressors equipped with effective and fully sealed air-cooling electromotor.